PILLARS - BLOCKS

High Quality

Spiderting with the best raw materials and using the latest production technology

Agility

Extensive stock and capacity to manufacture customised couplings within 24 hours

Custom

Design and manufacture for adapt

the coupling

to the machine

Experience

Over 70 years manufacturing power transmission couplings

HISTORY AND EVOLUTION OF OUR COMPANY

1952ORIGINS

Antonio Albert founded TALLERES ALBERT, a company dedicated to the repair of cars, trucks and tractors.

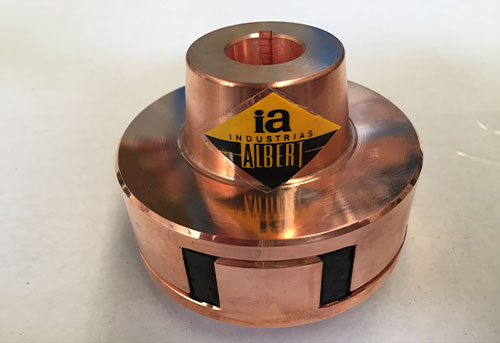

1959COUPLING

Design of the first coupling that solved the main problems in power transmission. Called the "Type A Coupling", it was a revolution in the Spanish market. That was when ACOPLAMIENTOS ALBERT was born.

1964SERIES PRODUCTION

Investment was made in innovative machinery to focus on mass production, which enabled production to increase fivefold.

1970R&D

The widespread application of couplings led to the creation of an Engineering Department. Its function: to design new couplings for mass production and help define customised solutions.1981NEW FACILITIES

Continued growth in demand led to investment in new facilities, new machinery and infrastructure. The portfolio included more than 300 references on the market.

1990INTERNATIONAL EXPANSION

Thanks to its high quality and excellent service, in the 2000s ACOPLAMIENTOS ALBERT crossed borders and focused on international manufacturers. Participation in major international trade fairs.

2001PORTFOLIO EXPANSION

Launch of the Estrella X system and the PB Series, designed to optimise maintenance costs. The INOX Series was added to the catalogue, featuring 316L stainless steel couplings manufactured in series. This significant investment in design allowed the company to exceed 1,000 references in stock

2010OEM STRATEGY

Engineering and business efforts are focused on helping machinery manufacturers optimise power transmission and costs by designing solutions based on customer needs2015PRODUCTION CAPACITY

Production lines are expanded with a LEAN design to cover the entire demand for couplings. Production, logistics and stock are optimised to remain true to our values.2019316L STAINLESS STEEL SERIES

With consolidated production, we digitise our internal processes and commit to a presence on social media to expand our reach with machinery manufacturers and industrial suppliers.

2024DIGITALIZATION

We became an international benchmark in the manufacture of 316L stainless steel couplings. We launched all our series in a stainless steel version, committed to quality and agility.