taper Inox

March 21, 2025XTC Series steel couplings

April 8, 2025FORGED STEEL FLEXIBLE COUPLINGS

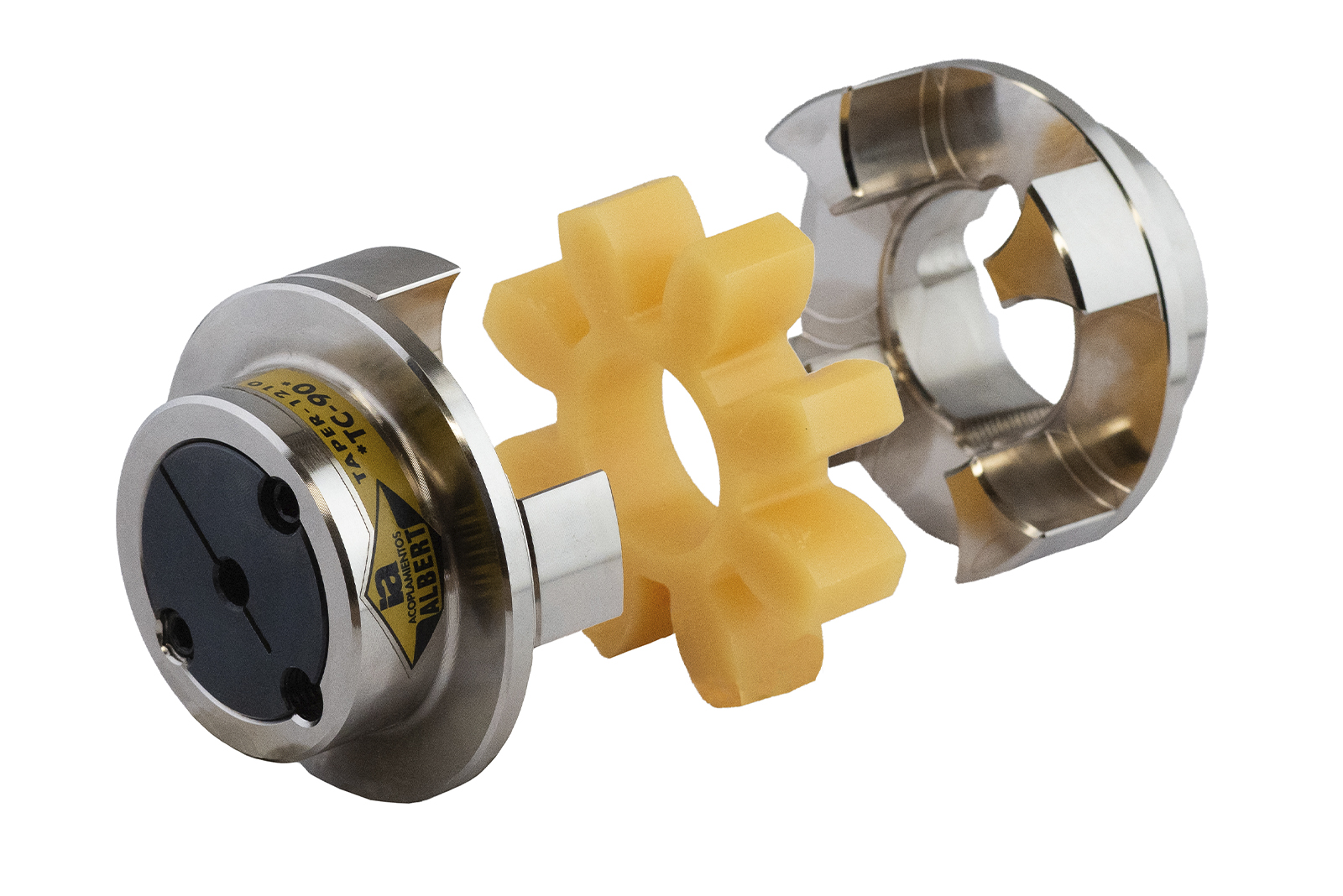

TC SERIES

0-10.700 Nm

DESCRIPTION

- Torsion-flexible claw couplings with a compact and lightweight design. Forged steel guarantees a long service life and excellent performance.

- The couplings feature a nickel surface treatment, which provides protection against corrosion.

- For the same Spider size, all series are interchangeable, offering great versatility for any application.

FEATURES

- Torsion-flexible Spider couplings for Taper Lock

- Taper Lock fastening available on the inside (TCI) or outside of the coupling (TC)

TECHNICAL SPECIFICATIONS

- Material: Forged Steel

- Surface Treatment: Nickel Coating

- ATEX version available: T4- Blue Spider and T6- Other Spiders

- Possibility to be mechanized according to drawing

- Dimensions in mm

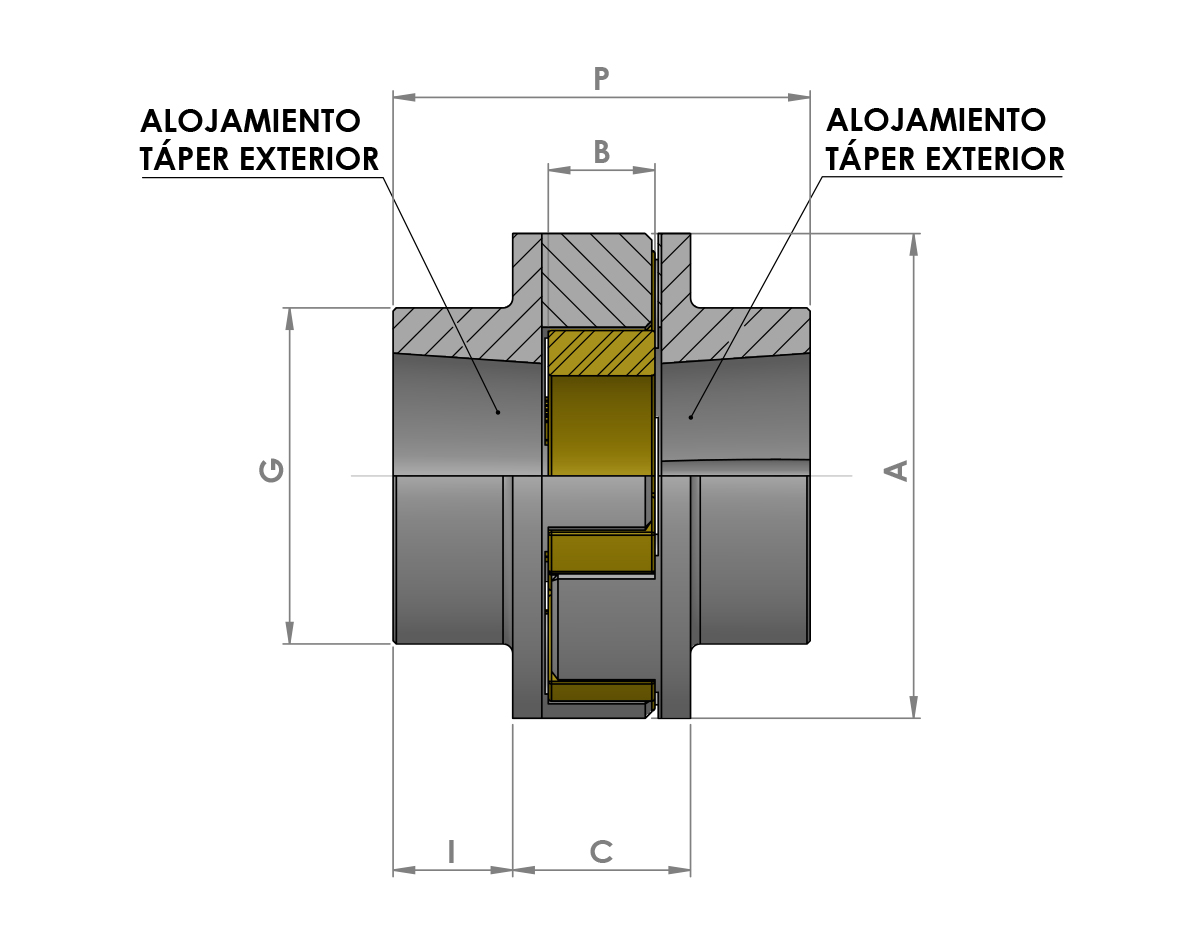

| Nominal torque (Nm) | |||||||||||||||

| REFERENCE | SPIDER A x B | SPIDER 85º ShA | SPIDER 90º ShA | SPIDER 92º ShA | SPIDER 96º ShA | SPIDER 98º ShA | SPIDER 64º ShD | R.P.M MAX | Taper Lock | P | C | G | I | Weight (kg) | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TC-75 | 75x16 | 80 | 80 | 100 | - | 170 | 210 | 9.500 | 1108 | 64 | 27 | 52 | 18,5 | 0,9 | |

| TC-90 | 90x20 | 160 | 160 | 210 | - | 370 | 460 | 8.000 | 1210 | 74 | 32 | 64 | 21 | 1,4 | |

| TC-105 | 105x20 | 270 | 270 | 310 | - | 525 | 650 | 7.000 | 1610 | 75 | 36 | 75 | 19,5 | 1,9 | |

| TC-120 | 120x20 | 400 | 400 | 420 | - | 695 | 860 | 6.000 | 2012 | 87 | 38 | 89 | 24,5 | 2,8 | |

| TC-150 | 150x28 | 900 | 900 | 1.050 | - | 1.575 | 1.950 | 4.500 | 2517 | 120 | 52 | 110 | 34 | 6,2 | |

| TC-200/35 | 200X35 | 1.900 | 1.900 | 2.400 | - | 3.600 | 4.500 | 3.500 | 3020 | 155 | 65 | 138 | 45 | 14 | |

| TC-200/40 | 200x40 | - | 3.050 | 3.300 | 4.125 | - | - | 3.500 | 3020 | 160 | 70 | 138 | 45 | 12 | |

| TC-245 | 245x40 | - | 4.890 | 5.000 | 6.250 | - | - | 3.000 | 4040 | 250 | 80 | 170 | 85 | 35 | |

| TC-300 | 300x50 | - | 7.900 | 8.500 | 10.700 | - | - | 2.300 | 4545 | 296 | 96 | 200 | 100 | 42,5 | |

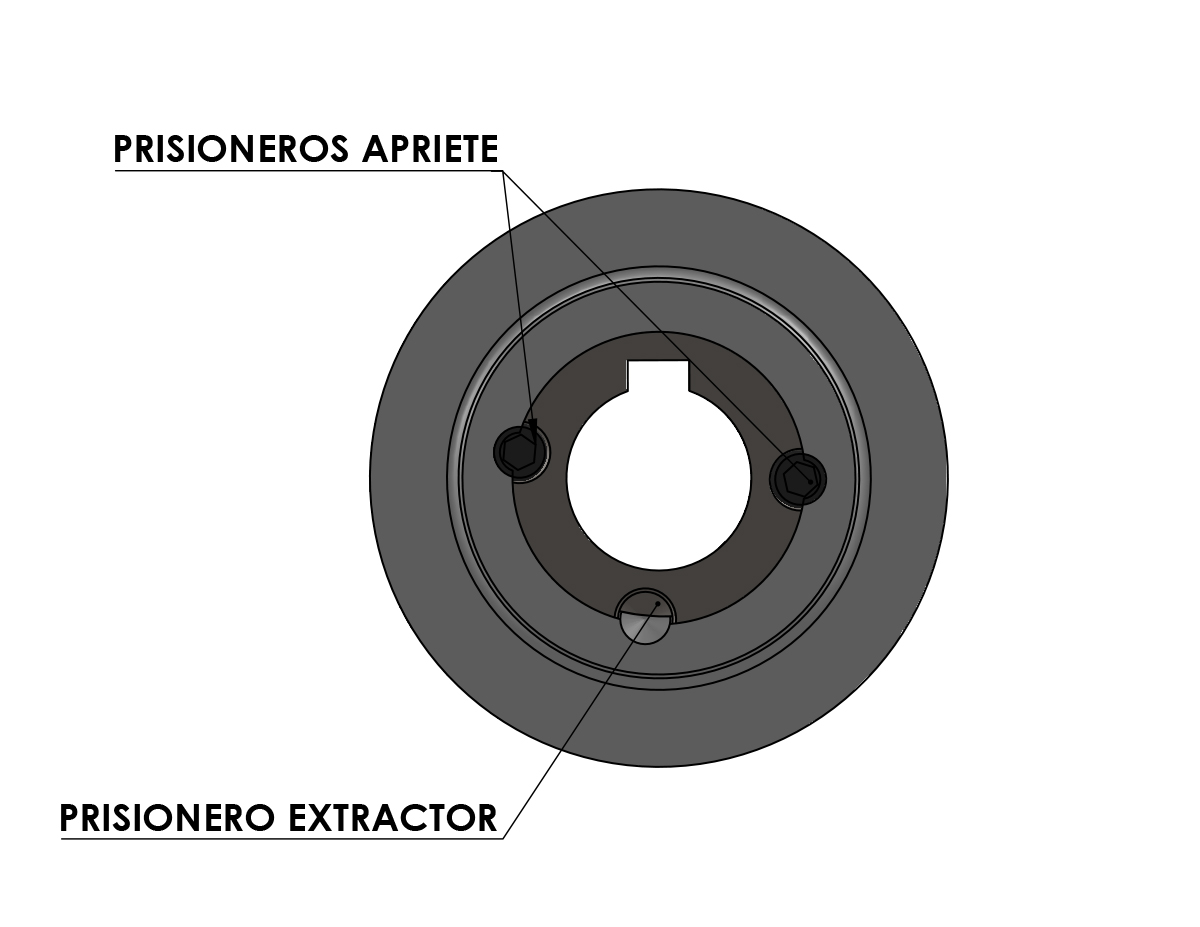

| Taper Lock | Available shafts | Length (mm) | Set screws | Par de Apriete (Nm) | Weight Ø Min (kg) |

|---|---|---|---|---|---|

| 1108 | 11-12-14-15-16-17-18-19-20-21-22-24-25-28 | 22,5 | 1/4″ × 1/2″ | 6 | 0,16 |

| 1210 | 12-14-15-16-17-18-19-20-21-22-24-25-28-30-32 | 25,5 | 3/8″ × 5/8″ | 20 | 0,32 |

| 1610 | 14-15-16-17-18-19-20-21-22-24-25-28-30-32-35-38-40-42 | 25,5 | 3/8″ × 5/8″ | 20 | 0,41 |

| 2012 | 15-16-17-18-19-20-21-22-24-25-28-30-32-35-38-40-42-45-48-50 | 32 | 7/16″ × 7/8″" | 31 | 0,75 |

| 2517 | 19-20-21-22-24-25-28-30-32-35-38-40-42-45-48-50-55-60-65 | 45 | 1/2″ × 1″ | 48 | 1,06 |

| 3020 | 25-28-30-32-35-38-40-42-45-48-50-55-60-65-70-75 | 51 | 5/8″ × 1 1/4″ | 90 | 2,50 |

| 4040 | 40-42-45-48-50-55-60-65-70-75-80-85-90-95-100 | 101 | 3/4″ × 1 1/2″ | 169 | 7,68 |

| 4545 | 55-60-65-70-75-80-85-90-95-100-105-110 | 115 | 7/8″ × 2″ | 192 | 10,50 |

NOTE: For each of the stars, the Maximum Working Torque is 2 times the Nominal Torque specified in the table.

TECHNICAL DATA SHEET

TECHNICAL SPECIFICATIONS

CERTIFICATIONS

ISO 9001

CERTIFICATIONS

ATEX