S Series steel couplings

March 20, 2025steel couplings TCI Series

March 21, 2025FORGED STEEL FLEXIBLE COUPLINGS

XS SERIES

0-3.000 Nm

DESCRIPTION

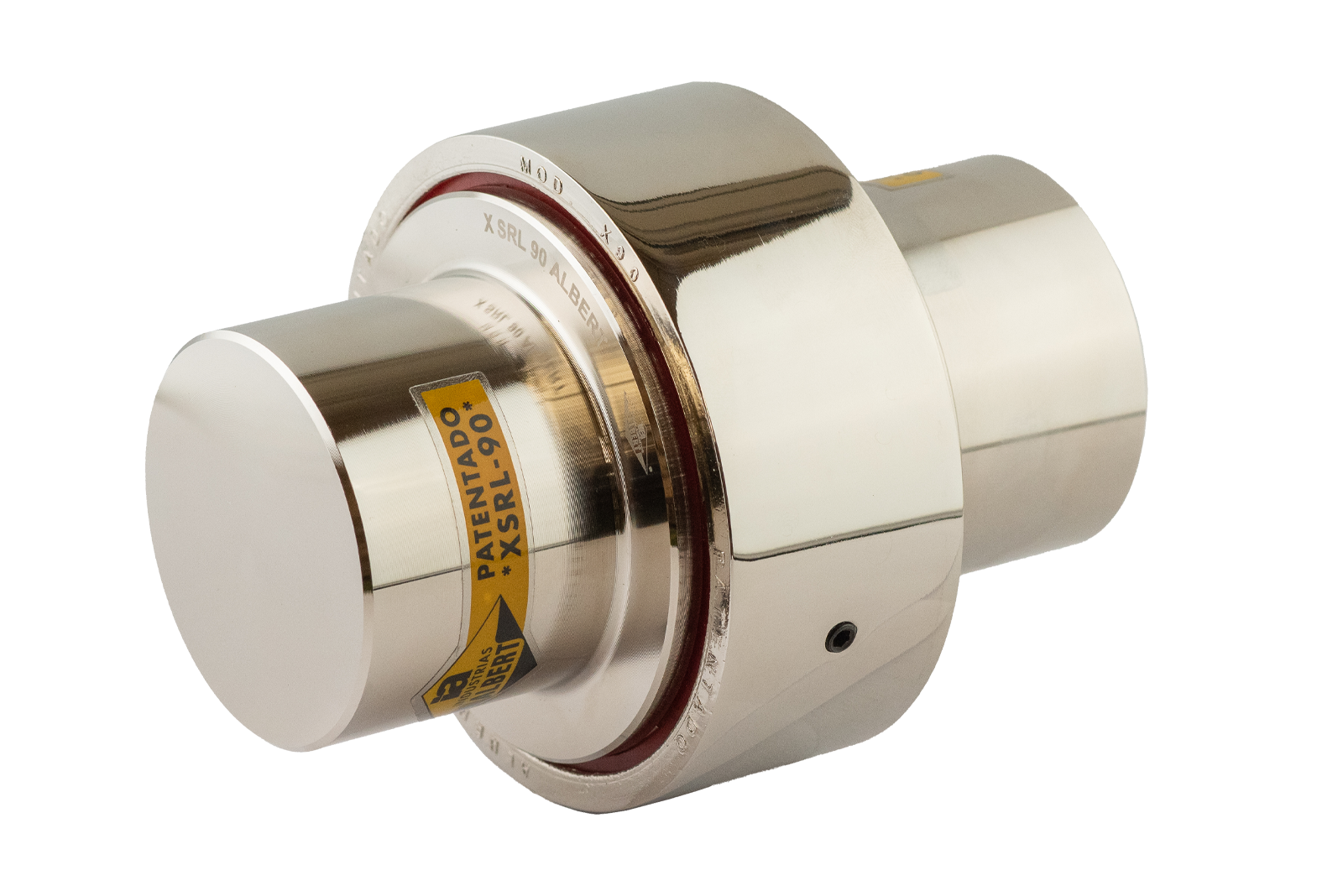

- Torsion-flexible claw couplings with a compact and lightweight design. Forged steel guarantees a long service life and excellent performance.

- The couplings feature a nickel surface treatment, which provides protection against corrosion.

- For the same Spider size, all series are interchangeable, offering great versatility for any application.

FEATURES

- Shaft fixing system Available with keyway or clamp

- Manufactured in various lengths

- External mounting Spider, designed for quick and easy maintenance

TECHNICAL SPECIFICATIONS

- Material: Forged Steel

- Surface Treatment: Nickel Coating

- ATEX version available: T4- Blue Spider and T6- Other Spiders

- Possibility to be mechanized according to drawing

- Dimensions in mm

| Nominal torque (Nm) | |||||||||||||

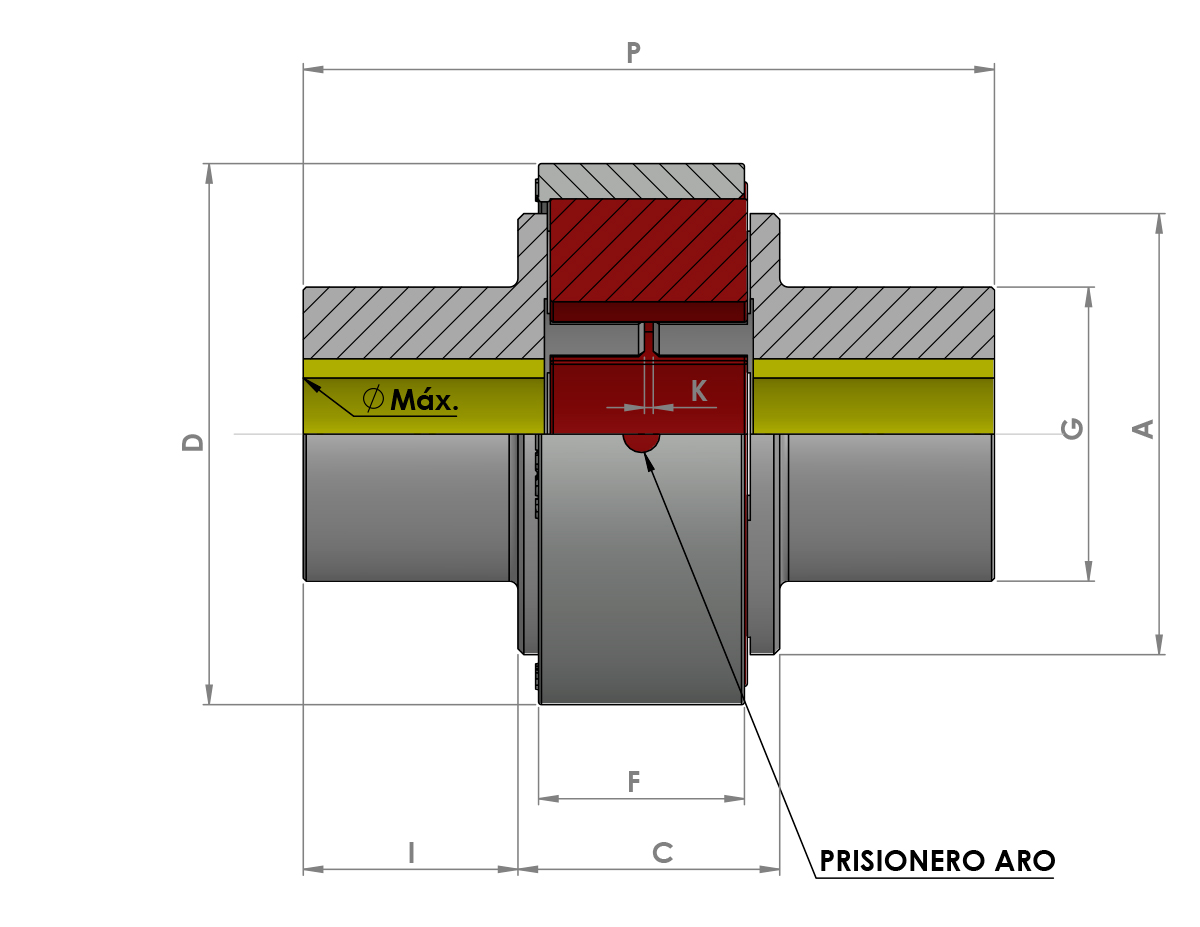

| REFERENCE | SPIDER A x B | MAXIMUM Ø AXES | SPIDER 92ºShA | Max R.P.M. | P | D | A | G | I | C | F | K | Weight (kg) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| XSR-50 | X-50 | 20 | 20 | 12.000 | 61,5 | 62 | 50 | 30 | 16 | 29,5 | 22 | 1,5 | 0,5 |

| XSRL-50 | X-50 | 22 | 20 | 12.000 | 73,5 | 62 | 50 | 32 | 22 | 29,5 | 22 | 1,5 | 0,6 |

| XSR-60 | X-60 | 28 | 50 | 11.000 | 77,5 | 74 | 60 | 40 | 19 | 39,5 | 30 | 1,5 | 0,9 |

| XSRL-60 | X-660 | 28 | 50 | 11.000 | 95,5 | 74 | 60 | 40 | 28 | 39,5 | 30 | 1,5 | 1,1 |

| XSE-60 | X60 | 28 | 50 | 11.000 | 111,5 | 74 | 60 | 40 | 36 | 39,5 | 30 | 1,5 | 1,2 |

| XSN-75 | X-75 | 28 | 130 | 9.500 | 89 | 92 | 75 | 41 | 22 | 45 | 35 | 2 | 1,3 |

| XSR-75 | X-75 | 38 | 130 | 9.500 | 93 | 92 | 75 | 50 | 24 | 45 | 35 | 2 | 1,6 |

| XSRE-75 | X-75 | 42 | 130 | 9.500 | 108 | 92 | 75 | 57 | 31,5 | 45 | 35 | 2 | 1,7 |

| XSRL-75 | X-75 | 38 | 130 | 9.500 | 118 | 92 | 75 | 50 | 36,5 | 45 | 35 | 2 | 1,8 |

| XSR-90 | X-90 | 45 | 270 | 8.000 | 110 | 108 | 90 | 60 | 28 | 54 | 43 | 2 | 2,7 |

| XSRL-90 | X-90 | 50 | 270 | 8.000 | 146 | 108 | 90 | 65 | 46 | 54 | 43 | 2 | 3,8 |

| XSE-90 | X-90 | 50 | 270 | 8.000 | 196 | 108 | 90 | 65 | 71 | 54 | 43 | 2 | 5 |

| XSR-105 | X-105 | 55 | 400 | 7.000 | 129 | 125 | 105 | 72 | 35 | 59 | 45 | 2 | 4,5 |

| XSRL-105 | X-105 | 55 | 400 | 7.000 | 165 | 125 | 105 | 72 | 53 | 59 | 45 | 2 | 5,6 |

| XSN-120 | X-120 | 55 | 600 | 6.000 | 123 | 142 | 120 | 70 | 31 | 61 | 45 | 2 | 5 |

| XSRL-120 | X-120 | 60 | 600 | 6.000 | 181 | 142 | 120 | 80 | 60 | 61 | 45 | 2 | 7,8 |

| XSN-135 | X-135 | 58 | 900 | 5.500 | 142,5 | 159 | 135 | 75 | 36 | 70,5 | 54 | 2,5 | 7 |

| XSRL-135 | X-135 | 70 | 900 | 5.500 | 212,5 | 159 | 135 | 90 | 70 | 72,5 | 54 | 2,5 | 11,7 |

| XSN-150 | X-150 | 60 | 1.350 | 4.500 | 158,5 | 175 | 150 | 80 | 40 | 78,5 | 60 | 2,5 | 9,3 |

| XSRL-150 | X-150 | 75 | 1.350 | 4.500 | 242,5 | 175 | 150 | 100 | 80 | 82,5 | 60 | 2,5 | 16,6 |

| XSN-175 | X-175 | 70 | 1.810 | 4.000 | 183 | 200 | 175 | 95 | 46 | 91 | 82 | 3 | 16 |

| XSRL-175 | X-175 | 85 | 1.810 | 4.000 | 273 | 200 | 175 | 115 | 90 | 93 | 82 | 3 | 26 |

| XSN-200/35 | X-200 | 100 | 3.000 | 3.500 | 207 | 227 | 200 | 110 | 54 | 99 | 90 | 3 | 24 |

| XSRL-200/35 | X-200 | 100 | 3.000 | 3.500 | 303 | 227 | 200 | 130 | 100 | 103 | 90 | 3 | 35 |

NOTE: For each of the stars, the Maximum Working Torque is 2 times the Nominal Torque specified in the table.

TECHNICAL DATA SHEET

TECHNICAL SPECIFICATIONS

CERTIFICATIONS

ISO 9001

CERTIFICATIONS

ATEX